When building custom drones for all-weather operations, proper waterproofing is crucial for protecting your investment and ensuring reliable performance in challenging conditions. This comprehensive guide will walk you through the essential steps and considerations for creating a weather-resistant drone.

Understanding IP Ratings

Before diving into waterproofing techniques, it’s important to understand IP (Ingress Protection) ratings. For drone operations:

- IP65 is typically sufficient for rain and light splashing

- IP67 provides protection against temporary immersion

- IP68 offers protection against continuous immersion

While achieving a full IP68 rating might be overkill for most applications, we recommend aiming for at least IP65 for reliable all-weather operation.

Essential Components to Protect

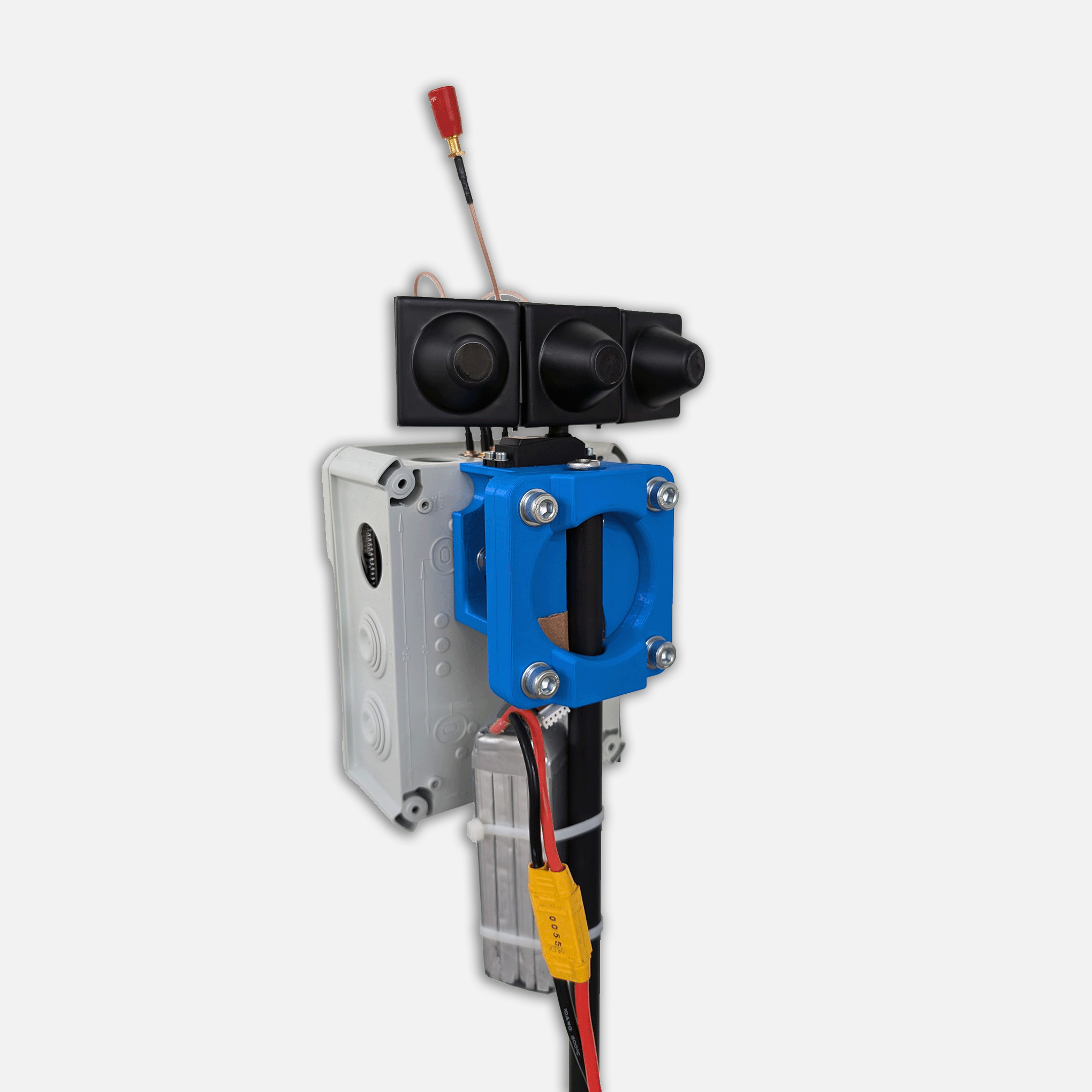

Flight Controller and Electronics

- Apply conformal coating to all circuit boards

- Use marine-grade silicone sealant around connector ports

- Install weatherproof connectors for all external connections

- Consider housing sensitive electronics in a sealed enclosure with gore-tex vents for pressure equalization

Motors

- Select motors with appropriate IP ratings (many quality drone motors come with IP55 or better ratings)

- Apply dielectric grease to motor bearings

- Install drain holes in motor mounts to prevent water accumulation

- Consider using brushless motors with sealed bearings

Battery Compartment

- Design with proper drainage channels

- Use rubber gaskets around battery door

- Install waterproof XT60H connectors

- Add silicon seals around power distribution board

Frame and Body

- Apply hydrophobic coating to exposed frame elements

- Install proper drainage channels in the frame design

- Use stainless steel or corrosion-resistant hardware

- Consider aerodynamic covers to deflect water

Step-by-Step Waterproofing Process

- Initial Preparation

- Disassemble the drone completely

- Clean all surfaces thoroughly with isopropyl alcohol

- Mark all areas requiring sealing

- Circuit Board Protection

- Apply multiple thin layers of conformal coating

- Allow each layer to cure completely

- Pay special attention to component legs and solder joints

- Mask connector pins before coating

- Frame Assembly

- Apply thread-locking compound to all screws

- Use marine-grade silicone sealant at frame joints

- Install rubber grommets for wire pass-throughs

- Apply corrosion inhibitor to metal components

- Final Assembly

- Install gore-tex vents in strategic locations

- Apply dielectric grease to electrical connections

- Seal all enclosure seams with silicone

- Create and verify drainage paths

Testing Protocol

- Initial Water Resistance Test

- Spray with garden hose from multiple angles

- Check for water ingress

- Verify drainage system functionality

- Electronics Verification

- Check all systems after water exposure

- Monitor for shorts or anomalies

- Verify sensor accuracy post-exposure

- Long-term Testing

- Perform graduated exposure tests

- Monitor internal humidity levels

- Document any corrosion or degradation

Maintenance Considerations

Regular maintenance is crucial for maintaining water resistance:

- Inspect seals monthly

- Replace degraded gaskets

- Clean drainage channels

- Reapply hydrophobic coatings as needed

- Check for corrosion after exposure to salt water

Common Mistakes to Avoid

- Overlooking thermal management in sealed enclosures

- Using incorrect sealant types that may degrade

- Creating water traps in the frame design

- Insufficient protection of electrical connections

- Neglecting pressure equalization in sealed compartments

Product Recommendations

Note: These are general categories rather than specific products. Research current options for your specific needs.

- Conformal Coatings: Look for silicone or acrylic-based options

- Sealants: Marine-grade silicone sealants

- Hydrophobic Coatings: Nano-coating solutions

- Connectors: IP67-rated or better

- Vents: Gore-tex protective vents with appropriate IP ratings

Safety Considerations

While waterproofing your drone is important, always remember:

- Maintain visual line of sight in adverse weather

- Consider wind conditions alongside precipitation

- Have redundant systems for critical operations

- Monitor weather forecasts and plan accordingly

- Follow local regulations regarding drone operation in adverse weather

Conclusion

Creating a truly weather-resistant drone requires attention to detail and proper planning. While the process may seem daunting, following these guidelines will help ensure your custom drone can operate reliably in adverse conditions. Remember to regularly test and maintain your waterproofing measures to ensure continued protection.